Some of the most asked technical Interview questions in Indian market for HVAC Design Engineer profile are discussed here.

1. What are the major components to be considered during heat load calculation?

Answer: All the sensible & latent heat gain to be considered while calculating heat load. Major heat load components are

- Solar Heat Gain through glass

- Solar Heat gain through walls & roofs

- Transmission/Radiation Heat gain through Glass

- Heat gain from lighting , appliances & other equipment’s

- Sensible & latent heat gain from people

- Heat gain from adjacent non-conditioned area

- Outside air heat gain

- Heat gain due to ventilation & infiltration

Click here to read more about components of heat load

2. What U values you consider for walls & glass, what is the unit of U factor?

Answer:

- U value of Glass: 0.54 for Double Pane ordinary glass with 45 deg inside venetian blind & 0.56 for Single pan glass with 45 deg inside venetian blind

- U value of Wall: 0.36 for 8 inch brick wall with 3/8 inch plaster or gypsum board.

- U Value for roof: 0.4 for roof without shade & 0.12 for shaded roof (underdeck insulation)

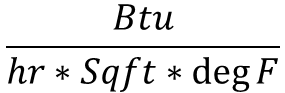

- Unit of U factor:

3. What is the significance of U factor ?

Answer: U factor also called as Transmission coefficient is the rate at which heat is transferred thru a building structure in Btu/ (hr)(sq ft)(deg F temp diff).

- The reciprocal of U value for any wall is the total resistance of this wall to flow of heat.

4.How much lighting load & appliance load to be considered in heat load calculation?

Answer:

- Lighting load 1 watts/sqft for LED lights or 1.25 watts/sqft for Non LED

- Equipment or appliance load for PC/laptop is around 0.15 KW per PC or heat load dissipation of equipment given by appliance manufacturer.

5.Which direction facing of building contributes to most & least heat gain?

Answer: WEST-facing wall contributes highest solar heat gain while wall/glass facing north experience lowest solar heat gain.

6.What are the types of heat gain that needs to be calculated in heat load?

Answer: There are mainly two types of heat gain,

- Sensible Heat gain: The Heat added without change in moisture content.

- Latent Heat gain: The heat added with change in moisture content of air.

7. What are types of heat transfer?

Answer: There three modes of heat transfer

- Conduction heat transfer:

- Convection heat transfer:

- Radiation heat transfer:

- heat transfer through walls is type of conduction heat transfer.

- heat transfer through glass is mainly radiation heat transfer from solar heat.

8. How do you calculate ventilation CFM in heat load calculation for comfort application?

Answer: Ventilation CFM to be calculated based on ASHRAE ventilation standard.

Ex: For commercial office application

Cfm per sqft=0.06

Cfm per person=5

Total CFM= Cfm based on area+cfm based on occupancy….(A)

Or

CFM based on ACPH= 1 ACPH (for office appliaction)…..(B)

Whichever is greater from (A) & (B) to be considered as final cfm.

Note: Refer ASHRAE ventilation standard for particular values of ACPH, cfm per person & cfm per sqft for different types of application.

(Reference: ASHRAE Standard 62.1-2019 Ventilation for acceptable indoor Air quality).

9.What is ADP ? What value of ADP you consider while calculating heat load for DX, VRF & CHW system?

Answer:

- Apparatus dew point is the effective coil surface temperature when there is dehumidification.

- This is the temperature to which all the supply air would be cooled if 100% of the supply air contacted the coil.

- For application involving cooling & dehumidification, the effective surface temperature is at the point where GSHF line crosses the saturation line on psychrometric chart. This effective surface temperature is considered to be the dew point temp of the apparatus. Hence the term Apparatus dewpoint (ADP) has come into common usage for cooling & dehumidification process.

Click here to read more about Apparatus Dew Point (ADP)

- For 75deg F inside room design temperature ,55% relative humidity & ESHF value 0.7 to 0.8 the ADP value varies from 52 degF to 56 degF.

- ESHF (effective sensible heat factor) = Effective room sensible heat(ERSH) / Effective Room Total heat(ERTH)

Reference: Carrier handbook of Air-conditioning design.

10. How to calculate Dehumidified Air CFM?

Answer:

Dehumidified Air CFM= Effective room sensible heat / (1.08*Dehumidified temp rise)

Dehumidified temp rise= (1-bypass factor) * (temproom – tempADP)

11.What are the inputs you require from client or site to design air-conditioning for any space?

Answer: Below are the inputs require from building survey,

- Orientation of building

- Application (use of space) & type of activity performed

- Physical dimension of space, AHU room, plant room

- Ceiling height/false ceiling height

- Columns & beams position & dimensions

- Glass/windows dimension

- people/ no of footprints (occupancy)

- Lighting

- Type of Appliance used or any heavy machinery like motors used

- Ventilation requirements

- Surrounding conditions (space above/below/adjacent are Airconditioned or not)

- Type of ceiling design

- Existing services routing like firefighting, electrical, plumbing etc.

- Drain termination points

- Location for indoor & outdoor units

- Indoor & outdoor design condition (specified by client)

- Type of operation (continues or intermittent)

- server/UPS room requirement

- underdeck insulation (if top floor)

12.How do you calculate basement ventilation requirements?

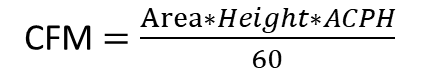

Answer: For basement ventilation Exhaust & fresh air fan CFM needs to be calculated by using below formula:

- Basement Exhaust Air CFM for Normal operation: ACPH=15 (reference National building code 2005).

- Basement Exhaust Air CFM during fire operation : ACPH=30 (reference National building code 2005).

- Fresh Air CFM= 0.8 * Exhaust air CFM at normal mode

13.What is Static pressure loss? how to calculate total & external static pressure of HVAC machine?

Answer: static pressure refers to the resistance to airflow in a heating and cooling system’s components and duct work.

The push of the air must be greater than the resistance to the flow or no air will circulate through the ducts.

This resistance can be due to any of the below factors in HVAC system:

- Resistance in straight duct due to friction loss

- Static Pressure loss due to duct fittings like bends, taper, elbow, y branch, takeoffs etc.

- Static Pressure loss due to ducting components fire & volume control dampers, canvass connections, flexible ducts, plenums, supply or return grills/diffusers, VAV box etc.

- Static Pressure loss due to other components like Fresh or exhaust air filters, scrubbers, exhaust hood etc.

- Static Pressure loss in internal components of unit such as cooling/heating coils, air filters, supply/exhaust fan etc.

To calculate External Static pressure add all the pressure loss values due to ducts, fittings & components which is external to the supply air fan outlet & select the fan size accordingly as per the CFM & calaculated ESP.

Total static pressure: external static pressure + internal static pressure (pressure loss due to internal components).

14.Where 3 way Valve & 2 way Valve are used in chilled water system?

Answer:

1. A 2 way valve is used in a chiller system with variable speed pump set. When the load reduces inside the room the sensor Pass signal to the actuator, though the valve closes/partialy close. which will create a pressure in the pipeline. transducer installed in the piping system sences this pressure change and send information/signal to the variable pump to reduce the pump speed. Which result in the low runnung cost/Power consumption.

2. A 3 way valve is used in a chiller system with constant pump set. Similarly when the load reduce inside the room the sensor pass signal to the actuator, result in opening/partial opening of the bypass opening(Third inlet in the 3way valve). Whic result in the flow of chilled water back to the piping system without entering the AHU/FCU.

Basically,

- use the 2 way Valve in the system that can withstand the variable water flow

- use the3 way valve in the systems that needs a constant water flow.

15.What is significance of Bypass line in chilled water system?

Answer: Bypass Line or Decoupler (Decoupler bridge) used for the piping design between the primary and secondary loops, the purpose of it is to have a minimum pressure drop, thus any change in flow rate in one loop will not affect the flow rate at the other.

Basically it is used to maintain the constant flow rate in chilled water system primary & secondary loop.

16.What is PIBCV & where it is used?

Answer:

Pressure Independent Balancing & Control Valve(PIBCV/PICV): The valve performs the function of a balancing valve and control valve in one unit.

- Controls the amount of liquid flowing through the pipe

- Automatically compensate pressure fluctuation in the system to maintain stable control.

Where it is Used?

- Used in Variable flow system at return outlet of AHU/FCU with room controllers and actuators to provide temperature control to each unit.

- In Constant flow systems, where the main pump doesn’t vary it’s speed, we will usually find 3 port control valves used to bypass the units and we can also use PICV’s here as flow limiters. This allows us to automatically balance the system and avoids overflow in part load operation.

17.If PIBCV is used at terminal units, weather balancing valve also require?

Answer: NO, PIBC will suffice both flow control & pressure balancing requirement.

18.What is the formula for calculating heat gain.

Answer:

Heat transfer through any surface like a wall can be calculated as: Q= U* A* dT

Can also be written as:

BTU/H= Area * Temp difference * heat transfer coeffecient(U factor)

Heat Transfer in BTUH

Area in sqft

Temp deff in Degree F

U factor in Btu/hour*degF*sqft

19.What is the formula for Calculating Heat transfer

Answer: Q= m*Cp*dT

Where, m = Mass flowrate of fluid

Cp= Specific heat capacity

dT= Temperature difference

The equation can also be written as:

BTU/H = 500*GPM*dT (for water as fluid used in chilled water system)

20.How to calculate Heat gain from Air flow or heat gain from outside air.

Answer: BTUH = CFM x (1-BF) x ΔT x 1.08

where; CFM is air flow rate

ΔT is temp difference inside & outside of the sapce

1.08 is Air factor of heat transfer

(1-BF) = (1-Bypass factor ) which is also called as contact factor (=0.88).

Click here to read more about bypass factor.

21.What are different methods of duct designing/sizing?

Answer: Methods of duct sizing are:

- Velocity reduction Method (for low velocity system)

- Equal friction method (most commonly used)

- Static regain Method

22. What is aspect ratio? what is value of aspect ratio?

Answer: Aspect ratio is the ratio of longer side to the shorter side of the rectangular duct.

Maximum permissible Aspect ratio is 1:4

23.What velocity you consider in Initial duct branch ,sub branch & branch takeoffs for commercial application?

Answer: Recommended Velocity for commercial/residential application:

- Intial/Main Branch: 1300-1400FPM

- Sub Branches: 800-1000 FPM

- Branch takeoffs: 300-500FPM

24.What velocity is considered while duct designing for exhaust air ventilation of basement/car parking area?

Answer: 1500-2000FPM

25.What friction rate is considered while duct sizing.

Answer: Friction rate used most commonly is:

0.1 inch of water Column per 100ft of duct

26.While designing cooling coil , what can be the coil entering & leaving dry bulb temperature:

Answer: for cooling coil

- Coil entering dry bulb temperature: 25-26 deg C

- Coil leaving dry bulb temperature: 12-13 deg C

27.Friction rate considered while designing CHW piping?

Answer: 4ft of water per 100ft

28.What Water velocity considered while designing CHW piping?

Answer: Not more than 2.5m/s (8fps)

29.What GPM per TR to are considered for chiller & cooling tower?

Answer:

- For Chiller: 2.4 GPM/TR

- For Cooling tower: 3 GPM/TR

30.For AHU panel selection what insulation type & thickness you will recommend?

Answer: We can recommend 50mm thick Polyurethane insulation between AHU panels.