Modern buildings, offices, shopping centers, hotels, hospitals and industries have simultaneous heating and cooling demand. In this article we will understand how Multifunction chillers are best solution for such demand.

Simultaneous loads occur in 90% of the annual cycle in such applications.

The demand of the building varies during the year according to:

- Outdoor temperature

- Occupancy

- Application/process

To meet the simultaneous need for heating and cooling there are two solutions:

- Conventional system with two energy generators (e.g. Chiller for cold water & Boiler for Hot water generation), less efficient because thermal energy of chiller is not utilized.

- Multifunction chiller: Single system to compensate both demands, which simplifies the system with high efficiency utilizing heat recovery.

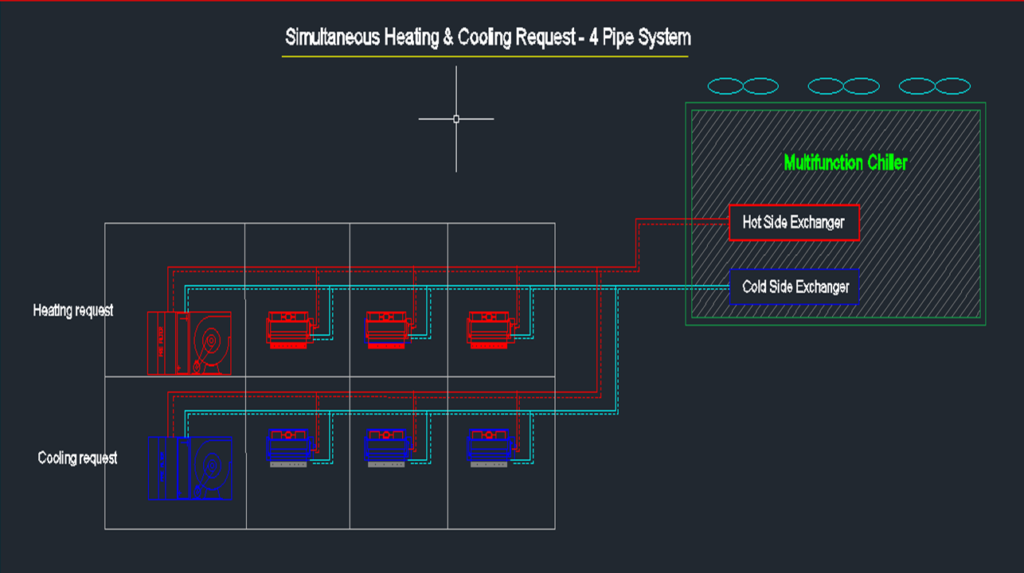

Multifunction Technology- 4 Pipe system

With a single multifunctional unit producing cooling and heating simultaneously, independently and efficiently, it is possible to replace both generators (boiler and chiller) working independently.

This kind of heat pump uses two separate heat exchanger for cold user side & hot user side with independent circuit for each.

Higher Efficiency:

In system where the multifunctional unit produces hot and cold water simultaneously, the efficiency of the unit is the sum of the cold and hot performances.

The overall efficiency is calculated as the ratio between the sum of the cooling and heating power supplied and the electrical power absorbed by the compressors alone, as the condensing section is not used.

The efficiency reaches its maximum values when the demands of the system are simultaneous and balanced.

Operating Conditions – 4 Pipe configuration

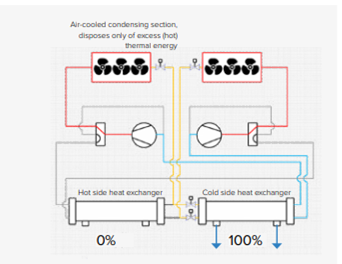

Scenario 1– Cooling Only Requirement: The unit will supply the cooling capacity on the cold side heat exchanger & the heat is rejected through the condenser

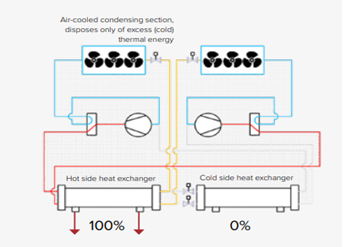

Scenario 2– Heating Only Requirement: The unit will supply the Heating capacity on the hot side heat exchanger & the cold energy is rejected through the condenser

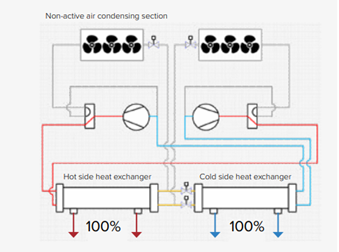

Scenario 3– Simultaneous cooling & Heating: The unit will supply Cooling capacity at the cold heat exchanger & heating capacity on hot heat exchanger side with complete energy recovery between two circuits. In this condition no energy is wasted outside of system & system operates on maximum efficiency.

Condenser side heat exchanger is not operational during this condition.

4 Pipe system Schematic

Benefits of Using Multifunction chillers

- Maximum efficiency: With Total recovery of energy, it is possible to supply simultaneous hot & cold water without wasting energy.

- The COP of the system is five times higher than conventional system.

- Lesser footprint: since the conventional chiller & boiler system replaced with single MF chiller more surface available for other use.

- Gas supply no longer required as in case of other heat generators

- Lower environmental impact because it does not use fossil resources & eliminates emission of toxic gases.

- Faster & cheaper installation & maintenance as compared to traditional system. As this system don’t need boiler gas connections & periodic checks are eliminated.

- Lower investment cost & less payback period of around 2 to 5 years.

- Yearly saving of 30% to 40% cost compared to traditional system.